Unlocking Success in Metal Fabrication: Your Comprehensive Guide to the Prototype Mold Factory at DeepMould.net

In today’s highly competitive manufacturing landscape, having a reliable and innovative prototype mold factory can be the decisive factor that elevates your business above the competition. At DeepMould.net, we pride ourselves on being a leading metal fabricator with extensive experience in creating high-precision, durable, and cost-effective prototypes that meet the most rigorous industry standards.

The Significance of Prototype Molds in Modern Manufacturing

Prototype molds are the cornerstone of successful product development. They enable manufacturers to realize their design concepts into tangible prototypes that can be rigorously tested for functionality, aesthetics, and manufacturability. Here are some compelling reasons why a top-tier prototype mold factory is essential:

- Accelerated Time-to-Market - Rapid prototyping allows quick iteration cycles, helping reduce overall product launch timelines.

- Cost Efficiency - Early detection of design flaws saves significant costs associated with downstream manufacturing errors.

- Design Validation - Physical prototypes enable thorough testing and validation, ensuring the final product aligns perfectly with customer requirements.

- Enhanced Innovation - The ability to produce complex molds supports innovative designs that push boundaries and add competitive edge.

DeepMould.net: The Pinnacle of Metal Fabrication Excellence

DeepMould.net has established itself as a hallmark of excellence in the realm of metal fabricators. With cutting-edge technology, seasoned engineers, and a client-centric approach, our prototype mold factory provides comprehensive solutions that span from initial concept to the final product. Our core competencies include:

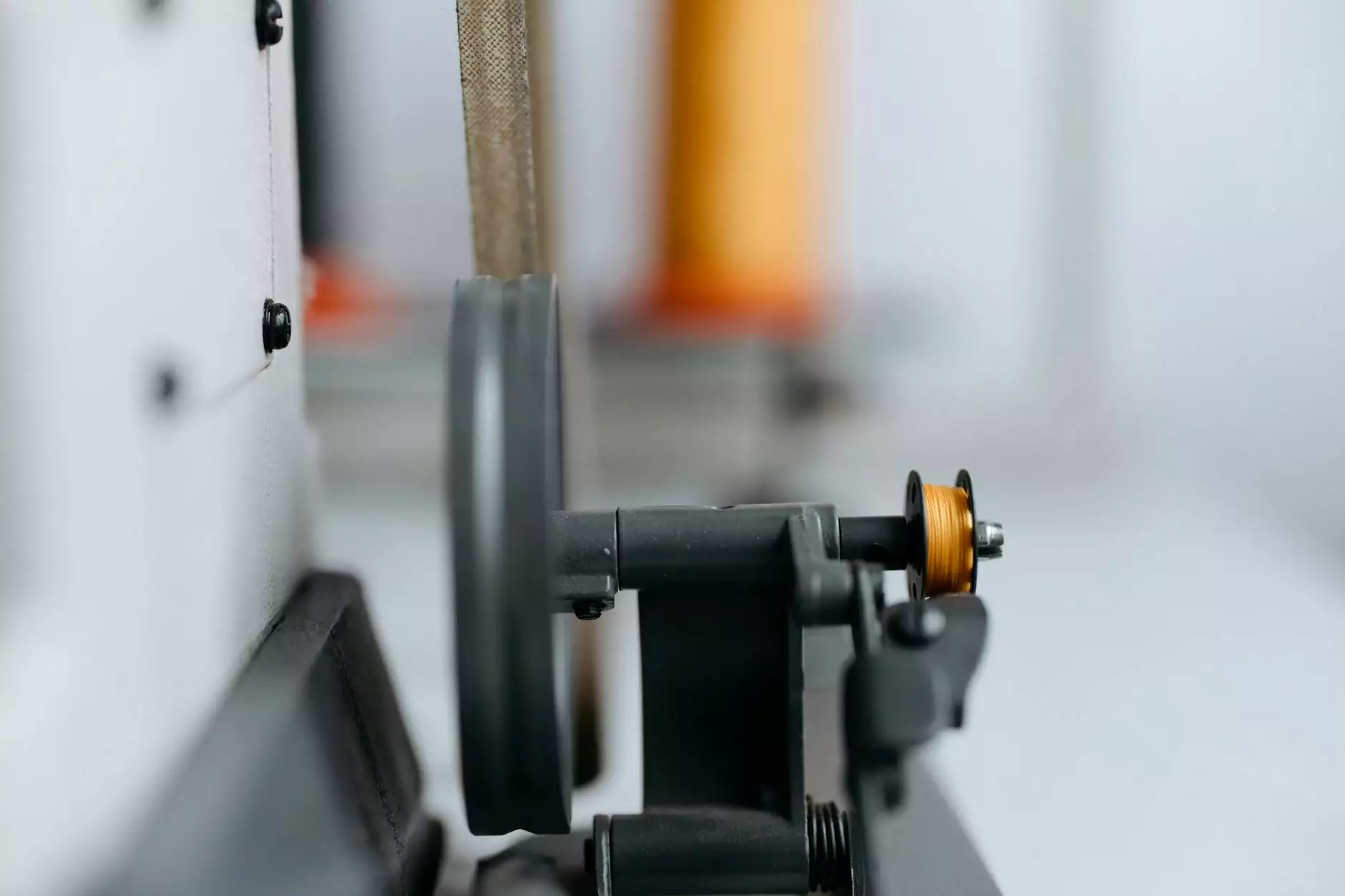

- Precision machining using CNC, EDM, and advanced milling technologies to achieve tight tolerances.

- Rapid prototyping capabilities that allow swift model creation for testing and refinement.

- Material expertise in working with diverse metals such as aluminum, steel, brass, and specialty alloys.

- End-to-end project management that ensures on-time delivery and quality assurance at every stage.

Why Choose DeepMould.net as Your Prototype Mold Factory

Partnering with DeepMould.net as your prototype mold factory offers numerous strategic benefits:

1. Unmatched Quality and Precision

Our commitment to precision engineering means every mold produced is tested thoroughly for dimensions and durability, ensuring your prototypes function exactly as intended and withstand the test of real-world conditions.

2. Advanced Technology and Tools

We invest continually in the latest fabrication equipment, including high-speed CNC machines, laser etching, and 3D scanning technology, enabling us to produce complex molds with high accuracy and fine detail.

3. Customization and Flexibility

Whether you require single-unit prototypes or small batch productions, our factory can tailor solutions to meet your specific requirements. We adapt our processes for different materials and design complexities efficiently.

4. Competitive Pricing and Fast Turnaround

Through optimized workflows and strategic resource management, DeepMould.net offers competitive pricing without compromising on quality. Our rapid prototyping services ensure you get your molds and prototypes promptly, minimizing project delays.

The Process: From Concept to Prototype at DeepMould.net

Understanding our comprehensive workflow highlights our dedication to excellence:

Step 1: Design Consultation

We collaborate with clients to refine design files, ensuring manufacturability and optimizing mold performance. Digital CAD models are analyzed for potential issues prior to machining.

Step 2: Material Selection and Planning

Based on the prototype's intended function, we advise on the best material choices, considering factors like thermal properties, machinability, and cost-effectiveness.

Step 3: Precision Machining and Mold Fabrication

Utilizing CNC machining, electrical discharge machining, and other advanced techniques, our skilled technicians craft molds with exceptional accuracy, adhering to your specifications.

Step 4: Inspection and Testing

Each mold undergoes rigorous inspection procedures, including coordinate measuring machine (CMM) verification, to ensure compliance with tolerance requirements and design specifications.

Step 5: Prototype Production and Delivery

Once approved, prototypes are produced using the fabricated molds, allowing clients to proceed with testing, validation, and refinement. Our delivery systems guarantee timely receipt of your prototypes worldwide.

Industries Benefiting from DeepMould.net’s Prototype Molds

Our expertise spans numerous sectors where precision, durability, and rapid turnaround are crucial:

- Automotive – Developing complex components and testing new designs.

- Consumer Electronics – Creating intricate enclosures and parts for gadgets.

- Aerospace – Producing high-strength prototypes adhering to strict safety standards.

- Medical Devices – Fabricating detailed biodegradable or biocompatible molds.

- Industrial Machinery – Testing robust parts for heavy-duty applications.

The Future of Metal Fabrication and Your Role in Innovation

As technology advances, the importance of a prototype mold factory that can keep pace with innovation becomes increasingly apparent. DeepMould.net remains at the forefront, integrating newer manufacturing techniques such as additive manufacturing (3D printing) for rapid mold prototyping, as well as smart automation systems to improve efficiency and quality.

Our vision is to help clients bring their ideas to market faster, with better quality and lower costs. Whether you are launching a new product line or iterating on existing designs, a partnership with DeepMould.net ensures you stay ahead of industry trends.

Partner with DeepMould.net: Your Trusted Metal Fabricator and Prototype Mold Specialist

Choosing the right metal fabricator for your prototype mold needs is critical to your project’s success. At DeepMould.net, we combine:

- Technical expertise in mold design and manufacturing

- State-of-the-art equipment

- Proven track record with numerous satisfied clients

- Customer-centric approach focusing on your needs and timeline

Our dedication to quality and continuous innovation makes us your ideal partner for transforming concepts into high-precision prototypes that propel your business forward.

Conclusion: Elevate Your Business with the Best Prototype Mold Factory at DeepMould.net

In the dynamic world of manufacturing, success hinges on quality, speed, and innovation. DeepMould.net’s experience as a premier metal fabricator specializing in prototype molds positions us as a leader capable of fueling your product development ambitions. By integrating cutting-edge technology, meticulous craftsmanship, and a comprehensive service approach, we help businesses accelerate growth and stay competitive in ever-evolving markets.

Reach out today to discover how our prototype mold factory can turn your ideas into reality—faster, more precise, and more cost-effective than ever before. Partner with DeepMould.net, and let’s build the future of manufacturing together.