Understanding Die Casting Die Manufacturers: A Comprehensive Guide

In the intricate world of manufacturing, die casting stands out as one of the most efficient and effective methods of producing complex metal parts. At the heart of this process are die casting die manufacturers, essential players in the metal fabrication industry. This article explores their role, the benefits of their innovations, and how they propel various sectors into the future with advanced technologies.

What is Die Casting?

Die casting is a precision manufacturing process where molten metal is injected into a mold cavity under high pressure. The mold, made from strong metal alloys, forms the shape of the desired part. Once the metal cools and solidifies, the die opens, and the part is ejected. This technique offers several advantages:

- High Accuracy: Parts produced are highly detailed, with tight tolerances.

- Rapid Production: Mass production capabilities allow for efficient manufacturing.

- Material Variety: Accommodates a range of metals, including aluminum, zinc, and magnesium.

The Role of Die Casting Die Manufacturers

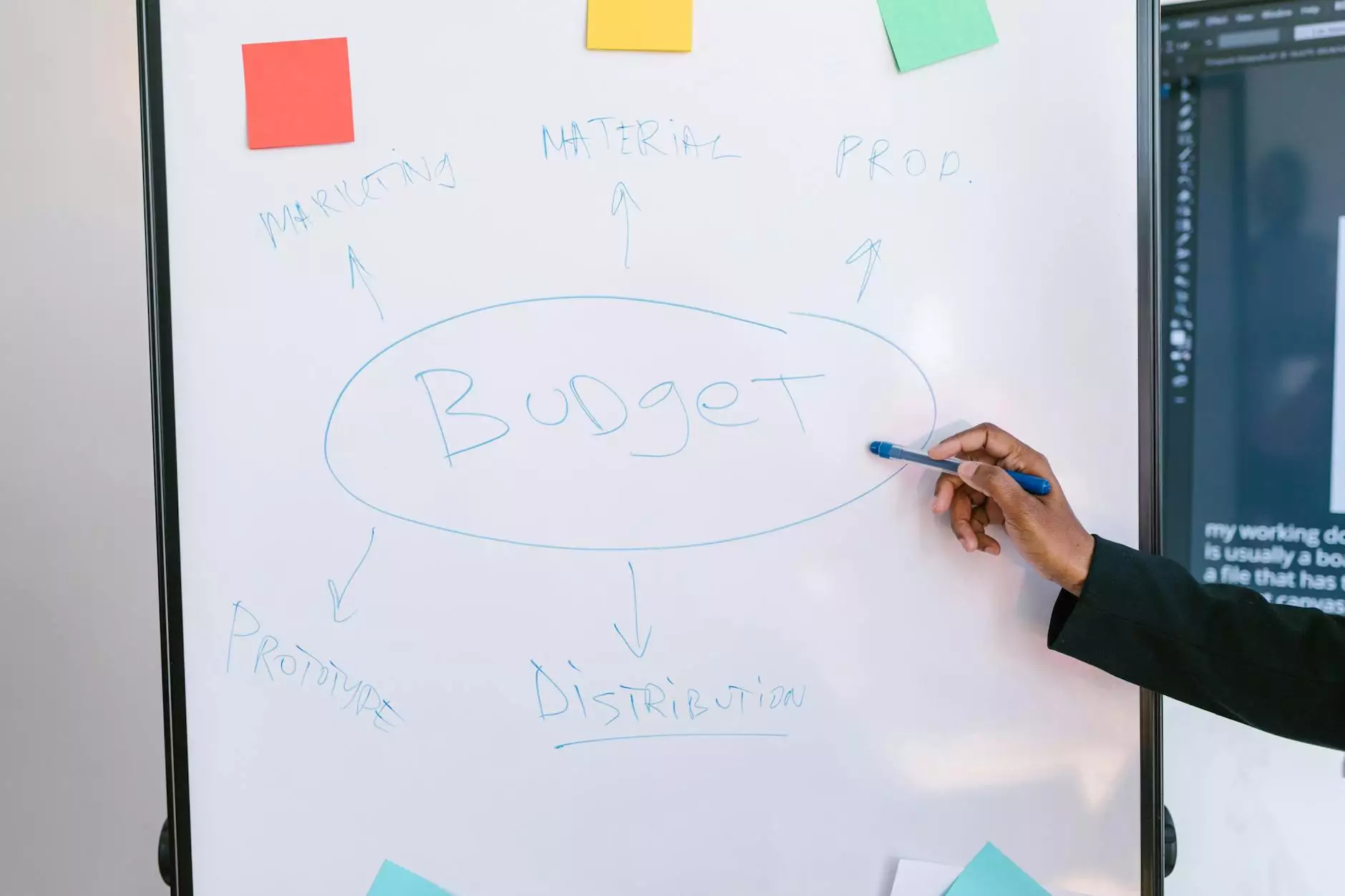

Die casting die manufacturers play a pivotal role in the die casting process. They design and fabricate the molds that are used for casting parts. Their expertise ensures that the molds have the necessary precision and durability to withstand the high pressures and temperatures involved in casting. This section covers key aspects of their role:

1. Design Engineering

The first step in the die casting process is mold design. The shape and functionality of the end product dictate the design of the die. Skilled engineers and designers work together to create a prototype using CAD (Computer-Aided Design) software. Factors to consider include:

- Part Complexity: Molds must be designed to precisely reproduce intricate details.

- Flow Dynamics: The die must allow molten metal to flow evenly throughout.

- Heat Transfer: Effective cooling systems must be integrated to ensure even cooling.

2. Precision Manufacturing

Once the design is approved, the manufacturing process begins. High-quality materials such as H13 tool steel are typically used due to their strength and resistance to wear. Advanced CNC (Computer Numerical Control) machining and EDM (Electrical Discharge Machining) techniques are employed for creating the die components with utmost precision.

3. Prototyping and Testing

Before full-scale production, prototyping is essential. Manufacturers create test dies to evaluate the performance, durability, and overall effectiveness. This stage is crucial for identifying potential issues and optimizing the design for mass production.

Benefits of Working with Die Casting Die Manufacturers

Partnering with die casting die manufacturers provides numerous advantages, especially for businesses looking to scale production while maintaining quality and cost-effectiveness:

1. Cost Efficiency

High initial costs of mold fabrication can be offset by the reduced expense per unit during mass production. Once the mold is made, the cost of each cast part decreases significantly, making it an economical choice for large runs.

2. Speed to Market

Due to the rapid production capabilities of die casting, companies can bring products to market faster. This speed is crucial in competitive industries where time-to-market can determine success.

3. High-Quality Products

Die casting produces parts with superior surface finishes and dimensional accuracy. The ability to achieve tight tolerances ensures that components fit together seamlessly, reducing the need for secondary operations.

Applications of Die Casting

Die casting die manufacturers serve a diverse array of markets. Here are some industry sectors that benefit significantly from die casting:

1. Automotive Industry

The automotive sector is one of the largest consumers of die cast products. Components such as engine blocks, transmission cases, and wheels are commonly produced using die casting techniques, owing to the need for durability and performance.

2. Aerospace Industry

In aerospace, precision and weight are critical. Die casting is frequently used for producing lightweight yet strong components that meet stringent regulations and standards.

3. Electronics Sector

As technology advances, so does the complexity of electronic devices. Die casting plays a vital role in manufacturing casings and housings for various electronic components, providing protection and enhancing aesthetics.

Innovation in Die Casting Technology

Continuous advancements in die casting technology have opened new avenues for manufacturers. Let's look at some of the latest trends and innovations:

1. Automation and Robotics

The integration of robotics in the die casting process enhances efficiency and precision. Automated systems can handle tasks such as loading materials into machines, removing finished parts, and even quality control inspections.

2. 3D Printing and Additive Manufacturing

3D printing technology is revolutionizing how dies are designed and manufactured. Rapid prototyping and custom dies can be created faster, allowing manufacturers to adjust designs quickly based on demand.

3. Sustainable Practices

With sustainability becoming a priority, die casting manufacturers are adopting methods to reduce waste and energy consumption. Innovations like closed-loop systems recycle excess material, contributing to a more eco-friendly manufacturing approach.