The Leading CNC Precision Parts Factory: A Comprehensive Guide

In the rapidly evolving world of manufacturing, CNC precision parts factories stand at the forefront, providing high-quality metal fabrication services that meet diverse industrial needs. This article will delve into the significance of CNC technology, the advantages of precision machining, and how partnering with a top-tier factory like DeepMould can enhance your business operations.

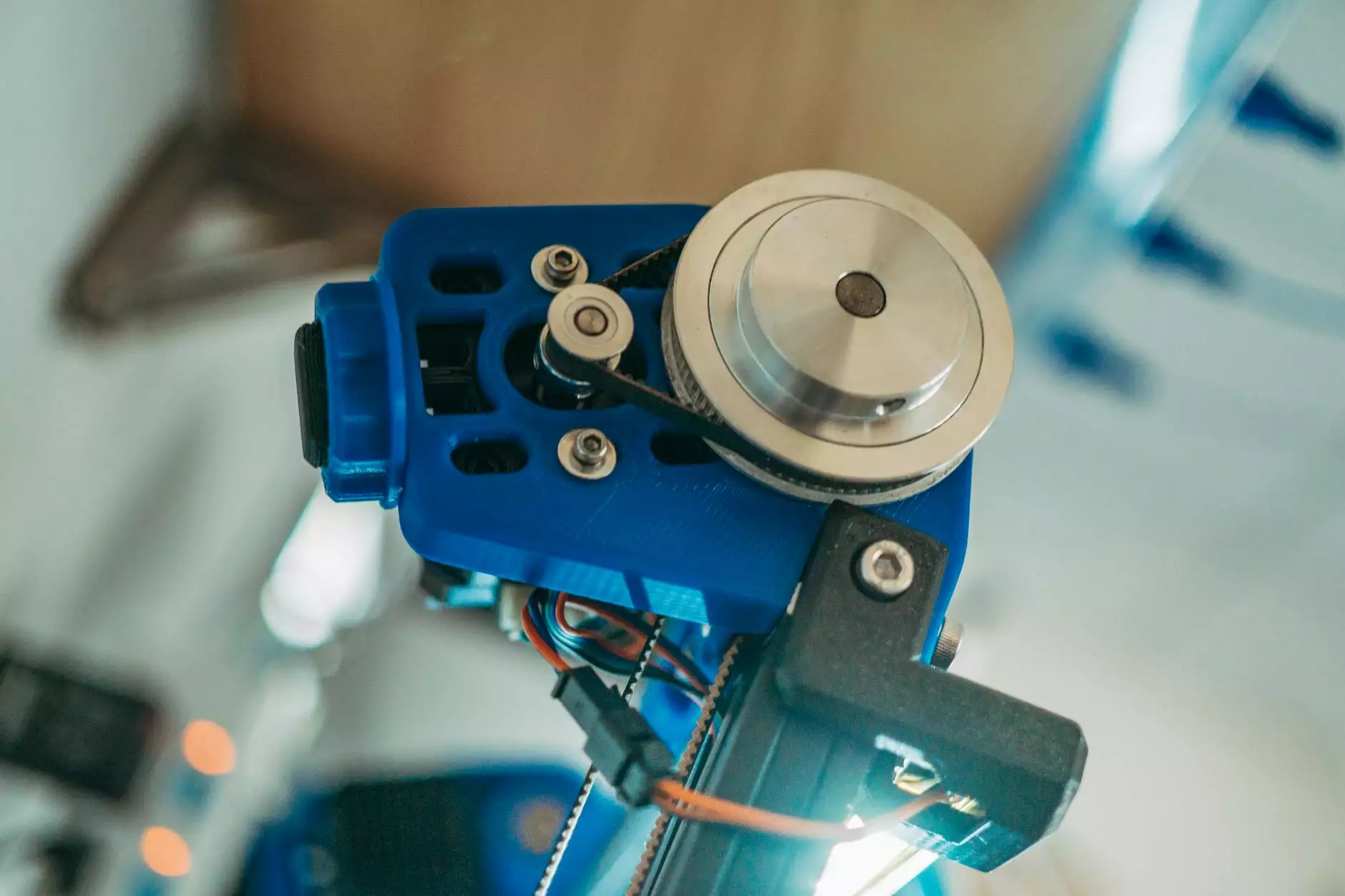

Understanding CNC Technology

CNC, or Computer Numerical Control, is a technology that utilizes computers to control machine tools. This innovative approach allows for a higher level of precision and efficiency in manufacturing compared to traditional methods. Here’s a breakdown of the key components:

- Computers and Software: The brain behind CNC machinery, providing precise programming for a variety of tasks.

- Machine Tools: Equipment such as lathes, mills, and routers that are driven by CNC technology.

- Raw Materials: The base materials such as metal, plastic, or wood that are transformed into final products.

The automation of the manufacturing process not only increases efficiency but also significantly reduces the chances of human error, ensuring consistent quality across all produced parts.

The Advantages of Partnering with a CNC Precision Parts Factory

Businesses seeking to optimize their production capabilities often turn to a reputable CNC precision parts factory. Here are some compelling advantages:

1. High Precision and Accuracy

One of the primary benefits of using a CNC precision parts factory is the unmatched accuracy achieved through CNC technology. Parts are manufactured to exact specifications, ensuring a perfect fit and function in the final assembly.

2. Increased Efficiency and Productivity

Automation reduces production time dramatically. Multiple components can be produced simultaneously, leading to faster turnaround times without compromising quality.

3. Cost-Effectiveness

While initial investments in CNC machinery may be significant, the long-term savings are undeniable. Reduced labor costs, fewer materials wasted, and the high rate of production make CNC machining a cost-effective solution.

4. Versatility

CNC machines are capable of handling various materials and manufacturing processes. Whether you need aluminum, steel, or plastics machined, a CNC precision parts factory can adapt to your needs.

5. Enhanced Design Capabilities

With CNC technology, complex parts and intricate designs can be realized with ease. Utilizing CAD/CAM (Computer-Aided Design and Computer-Aided Manufacturing) software, a CNC precision parts factory can bring your designs to life.

Applications of CNC Precision Parts

The applications of CNC precision machining span across various industries, showcasing its versatility:

- Aerospace: Manufacturing critical components with stringent quality standards.

- Automotive: Producing precision parts for enhanced vehicle performance and safety.

- Medical: Creating intricate components used in surgical instruments and devices.

- Electronics: Fabricating custom parts for devices and assemblies.

Each application demands high precision and reliability, making CNC factories an indispensable part of the supply chain.

Quality Control in CNC Precision Parts Factories

Maintaining quality in manufacturing processes is paramount, and CNC precision parts factories employ various methods to ensure top-tier products:

1. Rigorous Inspection Procedures

Quality assurance begins with the inspection of raw materials, followed by the monitoring of the manufacturing process. This often involves using advanced technology such as CMM (Coordinate Measuring Machines) to verify dimensions.

2. Documentation and Traceability

Each component produced is meticulously documented. Traceability is essential in industries like aerospace and medical manufacturing, where strict regulations apply.

3. Continuous Improvement Processes

Top CNC precision parts factories always strive for excellence. Implementing continuous improvement processes, such as Six Sigma or Lean Manufacturing, helps in minimizing waste and enhancing productivity.

Choosing the Right CNC Precision Parts Factory

Finding the perfect CNC precision parts factory for your needs can appear overwhelming. However, focusing on the following criteria can aid your decision:

1. Expertise and Experience

Look for factories with a proven track record in your particular industry. Their experience will contribute to a smoother production process and better understanding of specific requirements.

2. Technological Capabilities

Check the types of machinery and software in use. Advanced CNC equipment will ensure higher precision and efficiency in manufacturing.

3. Customer Service and Support

Effective communication and support are vital. A factory that is responsive to your queries and concerns will foster a better partnership.

4. Certifications and Standards

Verify that the factory adheres to international standards and certifications (such as ISO), ensuring that they follow best practices in manufacturing.

The Future of CNC Precision Parts Manufacturing

The future of manufacturing is bright with the continual advancements in technology. Trends affecting the CNC precision parts industry include:

- Integration of AI: Artificial intelligence will enhance machine learning processes, improving efficiency and accuracy.

- 3D Printing: Complementing CNC machining, additive manufacturing techniques are becoming increasingly integrated.

- Smart Factories: The rise of the IoT (Internet of Things) will allow for real-time monitoring and control of machinery, optimizing production flows.

Conclusion

In today’s manufacturing landscape, a reliable CNC precision parts factory can be a game-changer for your business. By embracing the advantages of CNC technology, you can achieve remarkable precision, efficiency, and cost savings. When partnering with an esteemed factory like DeepMould, you position your company for long-term success in a competitive market.

Investing in quality machining services is investing in your business’s future. Choose wisely and reap the benefits of precision manufacturing in your operations.