Revolutionizing Metal Fabrication: The Power of China Lathe Machine CNC Turning Parts

In the dynamic world of metal fabrication, precision, efficiency, and reliability stand as the pillars of successful manufacturing operations. As industries continue to advance, the demand for high-quality components that can meet stringent quality standards grows exponentially. At DeepMould.net, a leading name among metal fabricators, we understand the critical role that china lathe machine CNC turning parts play in elevating manufacturing excellence. This comprehensive guide explores the unparalleled benefits of utilizing China CNC turning parts, their technological edge, and how they reshape the landscape of metal fabrication across various industries.

Understanding the Significance of CNC Turning in Metal Fabrication

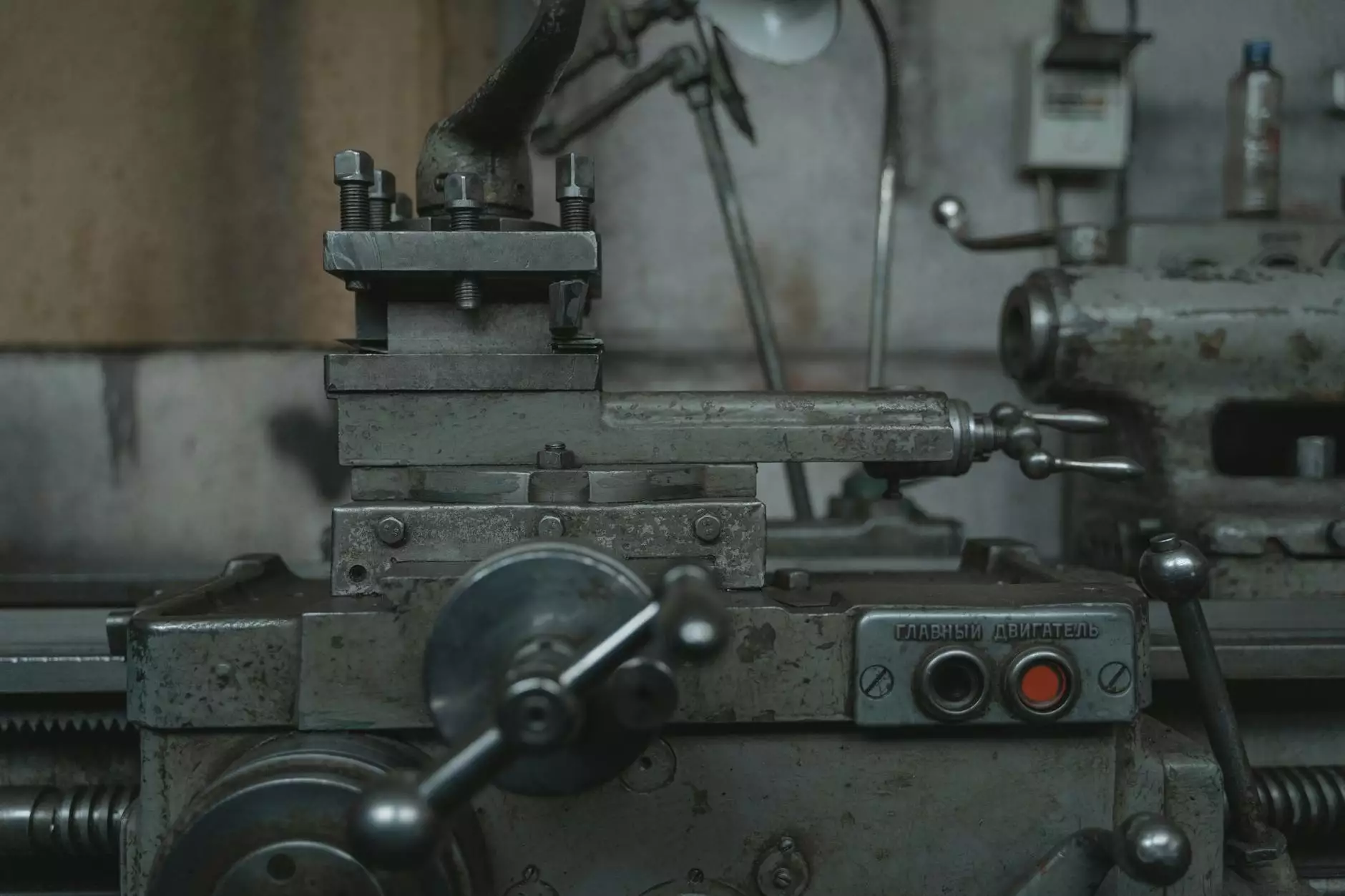

Computer Numerical Control (CNC) turning machines have transformed traditional manufacturing methods, delivering unparalleled accuracy and consistency in creating complex metal components. These advanced machines utilize computer programming to control the movement of cutting tools, enabling precise operations that manual machining simply cannot achieve. Among these, china lathe machine CNC turning parts are renowned for their high quality, scalability, and affordability, making them a preferred choice for modern metal fabricators.

The Evolution of CNC Turning Technology

From rudimentary manual lathes to sophisticated CNC systems, the evolution of turning technology has been driven by the necessity for greater precision, faster production cycles, and cost efficiency. China's manufacturing sector, in particular, has made significant strides in producing state-of-the-art CNC turning parts that meet international standards. These parts are integral components of CNC machines, ensuring stability, precise operations, and durability.

Why Choose China Lathe Machine CNC Turning Parts?

In the highly competitive realm of metal fabrication, selecting the right CNC turning parts can dramatically impact product quality and manufacturing efficiency. Here are compelling reasons to choose China-made CNC turning components through trusted suppliers such as DeepMould.net:

- Exceptional Quality and Precision: Manufactured using high-grade materials and advanced machining technologies, these parts ensure tight tolerances, smooth finishes, and long-lasting performance.

- Cost-Effective Manufacturing: China’s manufacturing industry benefits from economies of scale, enabling cost savings without compromising quality, perfect for large-scale production runs.

- Customization Capabilities: Chinese suppliers offer bespoke solutions tailored to specific machining requirements, facilitating diverse industrial applications.

- Rich Production Variety: From simple turning shafts to complex multi-axis components, the range of CNC turning parts is extensive, catering to various operational needs.

- Fast Lead Times and Reliable Delivery: Strategic manufacturing hubs in China ensure quick turnaround times and dependable shipping, minimizing downtime.

Applications of China CNC Turning Parts in Modern Industries

The versatility of china lathe machine CNC turning parts makes them indispensable across multiple sectors. Below are some prominent industry applications:

Automotive Industry

High-precision engine components, transmission parts, and chassis elements rely on CNC turning parts for ultra-fine tolerances and durability, promoting safety and performance.

Aerospace Manufacturing

In aerospace, the demand for lightweight, strong, and complex metal parts is critical. CNC turning components provide the required precision for turbine blades, structural elements, and landing gear parts.

Medical Device Production

Medical implants, surgical instruments, and diagnostic equipment depend on CNC turning parts for impeccable quality, dimension accuracy, and biocompatibility.

Industrial Machinery and Equipment

Heavy machinery manufacturing benefits from CNC turning parts for producing shafts, gears, and pistons that operate seamlessly under strenuous conditions.

Key Attributes of High-Quality China CNC Turning Parts

Choosing the right china lathe machine CNC turning parts involves evaluating several critical attributes:

- Material Integrity: Use of premium alloys, stainless steel, or specialized composites to ensure strength and corrosion resistance.

- Dimensional Accuracy: Maintaining tight tolerances (e.g., ±0.005 mm) for compatibility and performance.

- Surface Finishing: Achieving smooth surface finishes to reduce friction, improve wear characteristics, and enhance aesthetics.

- Design Flexibility: Customizable geometries to fulfill specific technical specifications and complex structures.

- Environmental Compatibility: Ensuring parts meet stringent environmental standards and are suitable for targeted industrial conditions.

Advantages of Partnering with DeepMould.net for CNC Turning Parts

DeepMould.net has established itself as an industry leader in supplying china lathe machine CNC turning parts. By partnering with us, you gain access to unparalleled advantages:

- Superior Quality Control: Rigorous testing and quality assurance processes guarantee each batch meets international standards.

- Cutting-Edge Manufacturing Facilities: Modern factories equipped with the latest CNC technology ensure precision and efficiency.

- Experienced Engineering Support: Skilled engineers collaborate with clients to develop optimized solutions for complex machining challenges.

- Competitive Pricing: Strategic sourcing and streamlined operations allow us to deliver cost-effective solutions for your business.

- Global Logistics and Support: Trusted supply chain networks guarantee timely delivery worldwide, supporting your production schedules.

Future Trends in CNC Turning and Metal Fabrication

The industry continues to evolve, integrating newer technologies to enhance production capabilities:

- Automation and AI Integration: Increasingly sophisticated CNC systems incorporating artificial intelligence for adaptive machining.

- Smart Manufacturing: IoT-enabled machinery providing real-time monitoring and predictive maintenance.

- Advanced Material Technologies: Development of new alloys and composites for greater performance and sustainability.

- Sustainable Manufacturing Practices: Emphasis on eco-friendly processes reducing waste and energy consumption.

How DeepMould.net Supports Your Metal Fabrication Success

Our commitment to excellence in metal fabricators extends beyond providing china lathe machine CNC turning parts. We focus on sustainable growth, innovation, and customer satisfaction:

- Technical Consultation: Assisting clients in selecting appropriate parts and customization options.

- Quality Assurance: Implementing strict quality management protocols at each manufacturing stage.

- End-to-End Solutions: Providing comprehensive support from design, prototyping, to mass production.

- Continuous Improvement: Regular updates and upgrades to manufacturing technology to stay ahead in the industry.

Conclusion: Embrace Advanced Manufacturing with China CNC Turning Parts

The landscape of metal fabrication is advancing rapidly, and embracing high-qualitychina lathe machine CNC turning parts is essential for manufacturers aiming for excellence. Companies seeking reliable, precise, and cost-effective components will find their ideal partner in DeepMould.net, who is committed to delivering innovative solutions tailored to your unique needs. By leveraging China's manufacturing prowess and cutting-edge technology, your business can achieve new heights in quality, efficiency, and competitiveness.

Investing in superior CNC turning parts is not just a purchase—it's a strategic move toward manufacturing mastery. Embrace the future of metal fabrication today with DeepMould.net and experience unparalleled support, quality, and innovation.